Inventory Control in real time

Put supply chain operations and control at your fingertips to prevent product out-of-stock events and stay on top of materials.

Accurate Product Costing

Calculate and maintain the precise product cost based on your bill of materials (BOM) and manufacturing activities.

Master Production Schedule

Maintain control over the production schedule and manufacturing procedures. MakeSmart offers a consistent platform to track a client order.

Shop Floor Control

Shop Floor Control will assist in the tracking, scheduling, and reporting of activities inside your manufacturing plant.

MakeSmart Web

If you are a small manufacturer looking to simplify your business workflows, with easy sales fulfilment, visual production planning and life inventory management, then you come to the right place.

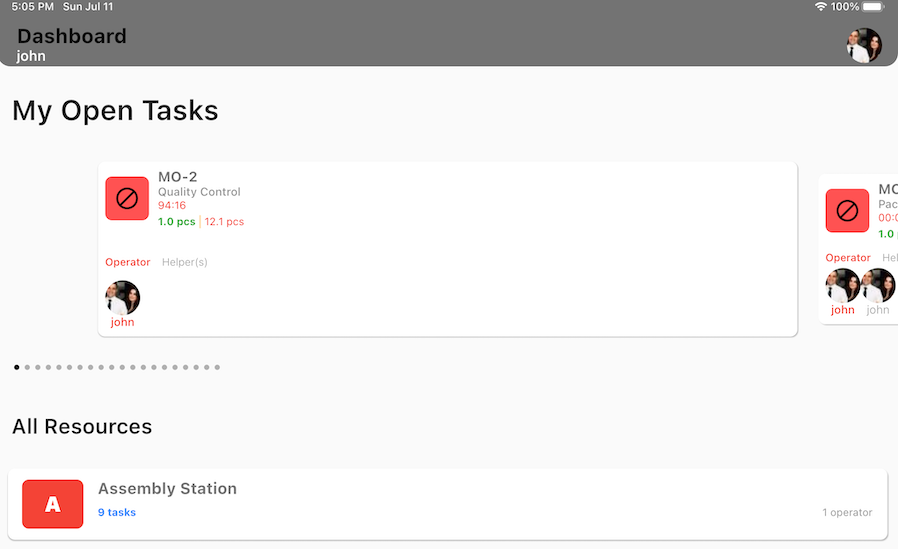

MakeSmart Mobile

MakeSmart Mobile App is an extension of the SalesFront MRP module. Factory operators will manage the tasks assigned, book raw materials and track duration of tasks.

Software that breathes life into your manufacturing company.

With a manufacturing ERP that moves as quickly as your sales and inventory, you'll have the data you need when you need it.

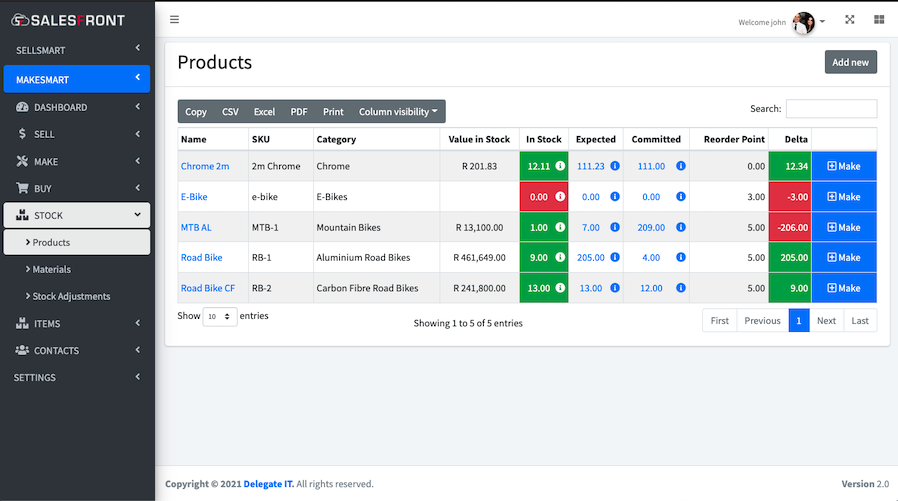

Stock Control and Inventory Management.

To avoid stock-outs, keep track of supplies and product inventories.

- Get complete inventory management for both finished goods and raw supplies.

- To avoid stock-outs, automate inventory operations and set reorder points.

- Real-time inventory tracking of on-hand, committed, and anticipated goods.

All of your production scheduling and resource management needs are taken care of in one location.

All of your critical resources can be optimized from a single point of view.

- Using real-time data, make precise production and purchasing decisions.

- Ensure that inventory levels are optimal at all times.

- Prioritize manufacturing based on the availability of raw materials.

- Get task-level control and visibility into each task's status.

- Calculate manufacturing costs based on your bill of materials and operations with ease.

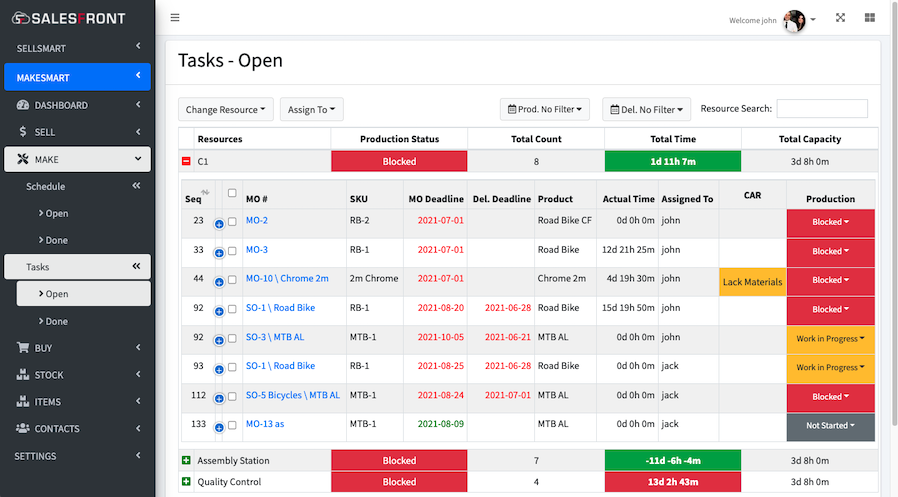

Control the factory floor level, from scheduling to task prioritizing.

Factory operators use MakeSmart Mobile App to handle tasks given to them and to book raw materials.

- Allocate tasks to factory employees based on product operations.

- Stay informed while operators start, end, pause and resume tasks in real time.

- Every task in the app has a make order, an ingredient list and attachments.

- Download manuals, instructions and diagrams to complete the task.

- Keep track of how long it takes you to finish a task in total active time.

- For each task, record the quantity of goods made in real time.

- Stay on top of raw materials or goods required to complete the task.

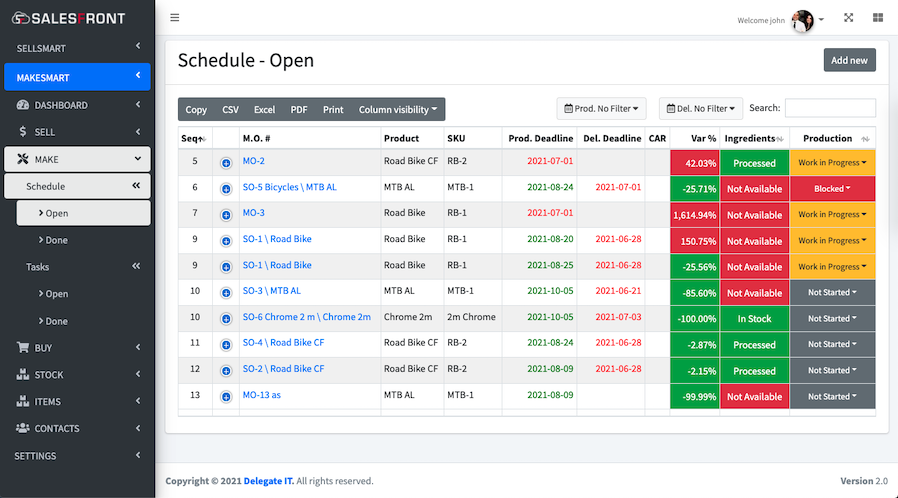

Simple yet powerful Master Production Schedule

Master Production Schedule (MPS) to plan for the manufacture of certain products based on demand, priority, ingredients and resources availability.

- Prioritize manufacturing tasks by dragging and dropping them.

- Check the ingredient's availability to fulfill a make order.

- Determine the likelihood of delays due to material supply lead times.

- Obtain accurate projected completion dates to keep sales teams informed.

- Have access to a real-time production status report at the floor level.

- Monitor variances in costs computed at many levels of the BOM and operations.

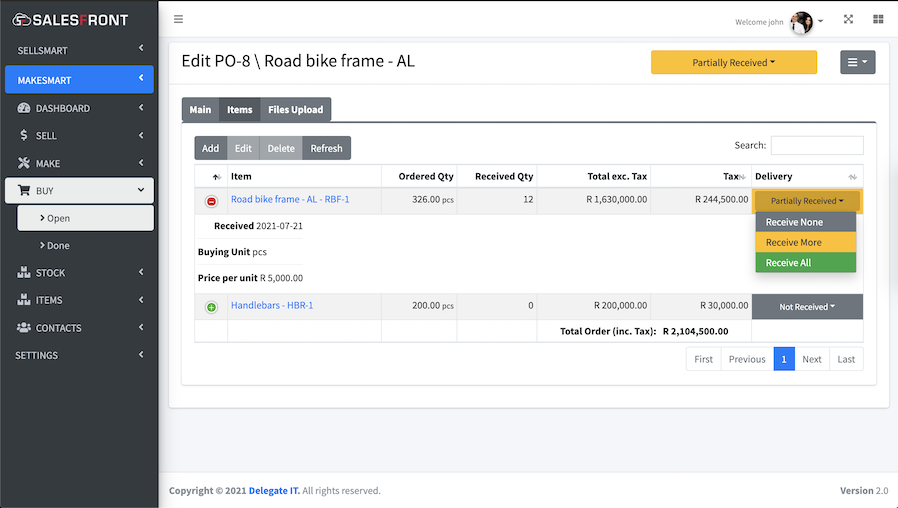

Purchase order tracking and stock level optimization.

Management of purchase orders in a structured and automated manner.

- Open purchase orders based on production schedule and materials requirements.

- Update purchase orders delivery in parts or in full.

- Choose the optimal time to place orders with suppliers

- Track supply chain delays to keep everyone in the loop and make informed decisions.

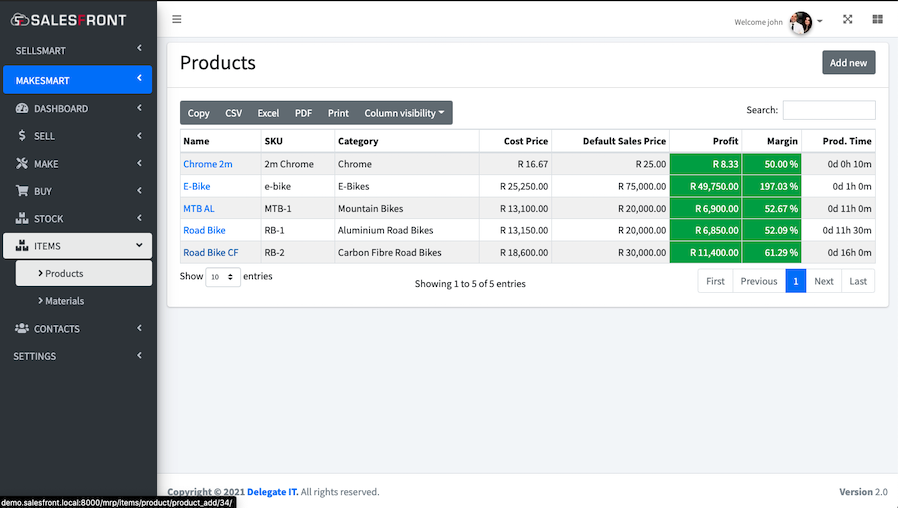

Accurate manufacturing cost calculation for products

Multi-level BOM and multi-level product costing.

- Determine the true quantity of raw materials and products utilized in the manufacturing process, and compare the expected and actual expenses.

- Make multi-level BOM products and properly compute multi-level pricing.

- Generate a precise product pricing determined by market competition and product margins.